The laboratory is also focused on the development of Industry 4.0 solutions. Its high-educated members use various technologies related to the 4th industrial revolution e.g., big data, augmented reality, machine learning, machine vision, additive manufacturing techniques, or cloud computing, aiming to build cyber-physical systems able to increase the industry’s profitability. Furthermore, among the laboratory’s goals included the role of catalyst in the application of innovative systems across the industry, which would help the worldwide production cost-cutting avoidance. This is happening through the assessment of its technology maturity level while preparing its equipment to be harmonized with the Industry 4.0 technologies.

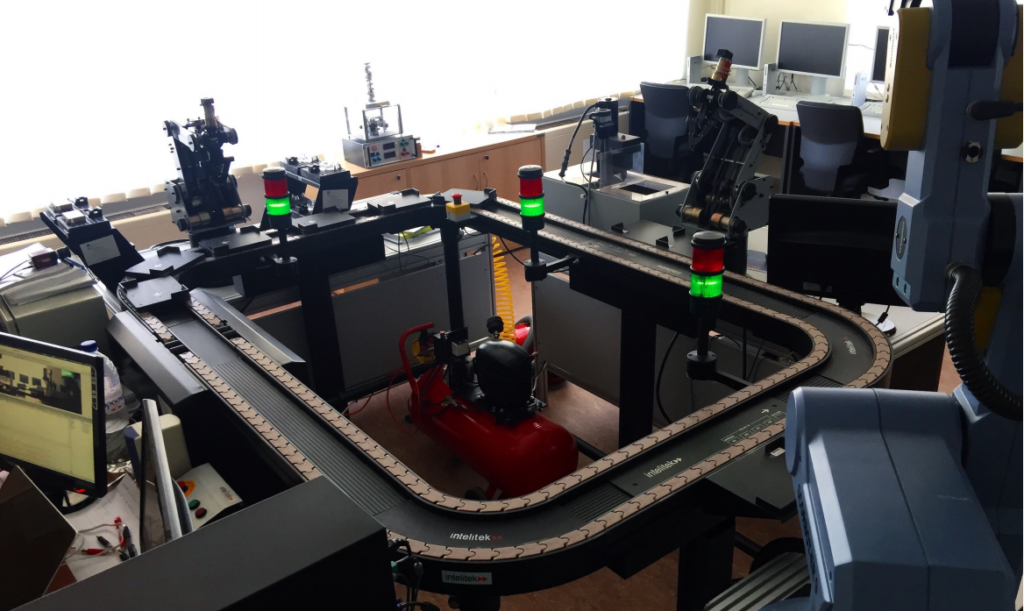

The laboratory’s pilot applications are implanted on the CIM cell in order to enable the 4th Industrial revolution capabilities. The real-scale educational Computer Integrated Manufacturing (CIM) cell consists of three workstations.

One of our successful implementations is the vision-based product tracking pipeline for cyber-physical-production systems.

As the incoming visual measurement enters the pipeline, a product search algorithm takes place. When the system locates the proper element, visual features are extracted and tracked among consecutive frames. Finally, its position is uploaded to a cloud platform for external usage.

Another application concerning the I4.0 focuses on the field of maintenance. Nowadays, when a module needs to be repaired most of the work is done via qualified engineers. However, in most cases, they are not factory members but constitute specialists who manufactured the machines.

The proposed I4.0 application provides the required knowledge to a non-expert engineer to tackle system failures using augmented reality technology, remote and cloud computing. This way a recovery-time reduction is achieved, which implies an overall system performance increase.

In addition, factory staff can be trained in machinery maintenance and the deployment times can be reduced. Our tool can identify the points of intervention as well as the actions required by the user reducing unnecessary body movements and wrong actions.